Description

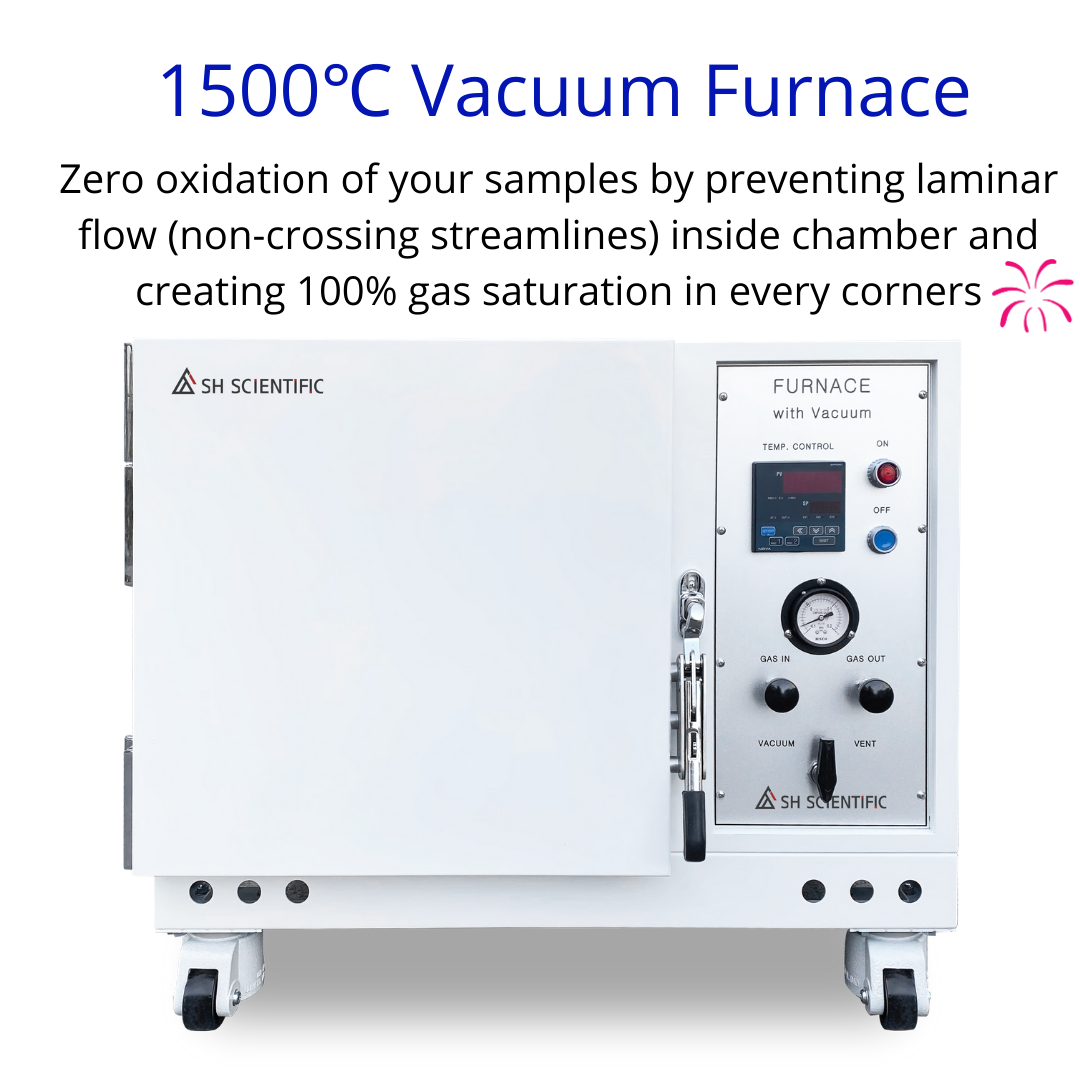

- Zero oxidation thanks to 100% gas saturation environment

- CVD (chemical vapor deposition) furnace for GRAPHENE development and production

- Preventing the non-crossing streamlines phenomenon in vacuum chamber

- Create your multiple atmospheric environment (burning and ashing in air, purging air and pulling vacuum, flowing inert gas and sintering)

- No limitation on materials sizes compared to the ones with tube furnace

- Support hardening, annealing, tempering, brazing and sintering with or without vacuum

- Vacuum heat treating and vacuum brazing

- Vacuum gauge for visual pressure monitoring

- Recommended ideal running temperature is below 1350℃

- Ceramic fiber materials which are not classified as carcinogenic

- Vacuum close and vent valve

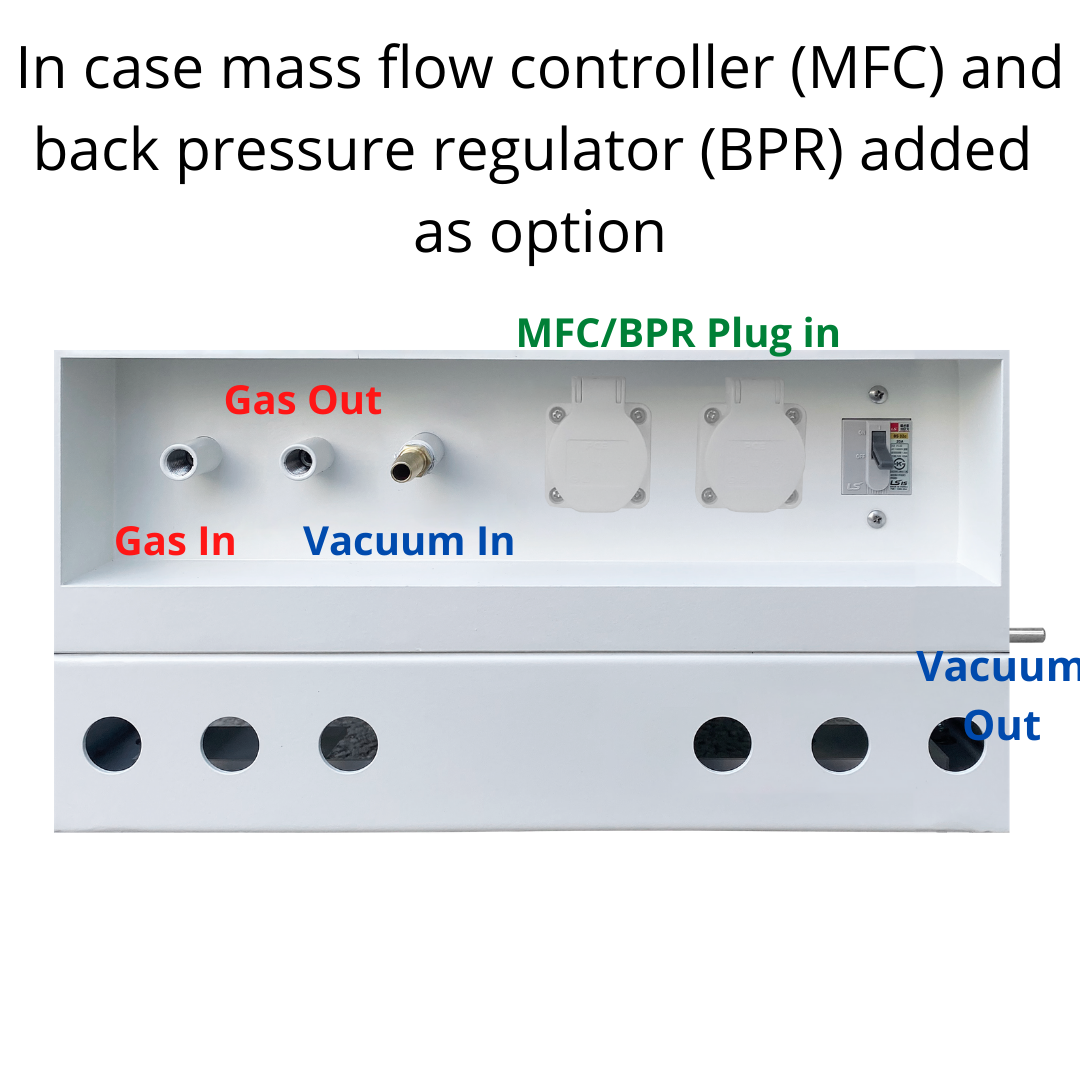

- Gas inlet/outlet ports

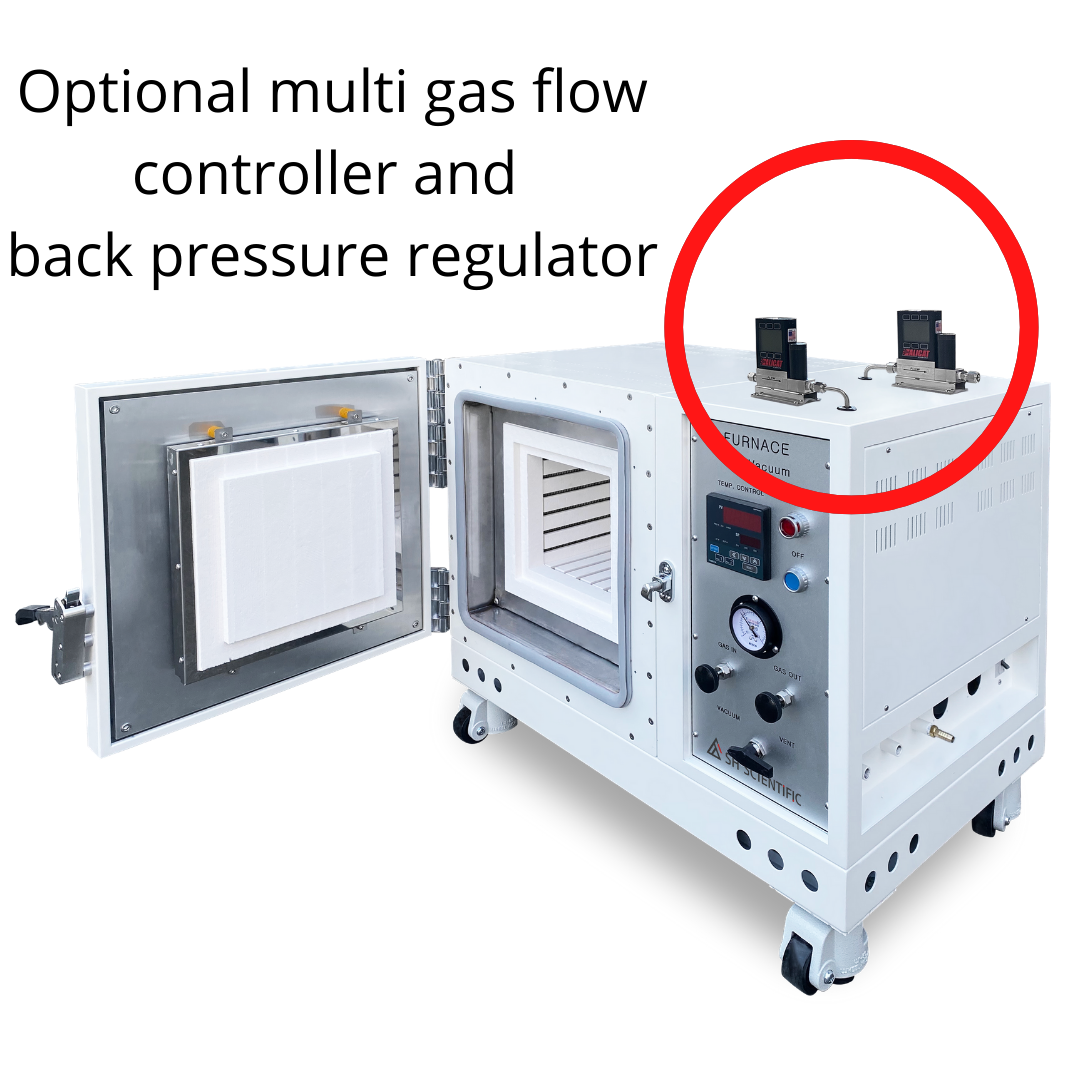

- Mass flow controller for 98 kinds of various gases including Argon, Nitrogen and Hydrogen. Option

- Back pressure regulator. Option

- Digital vacuum meter. Option

- Over temperature protector

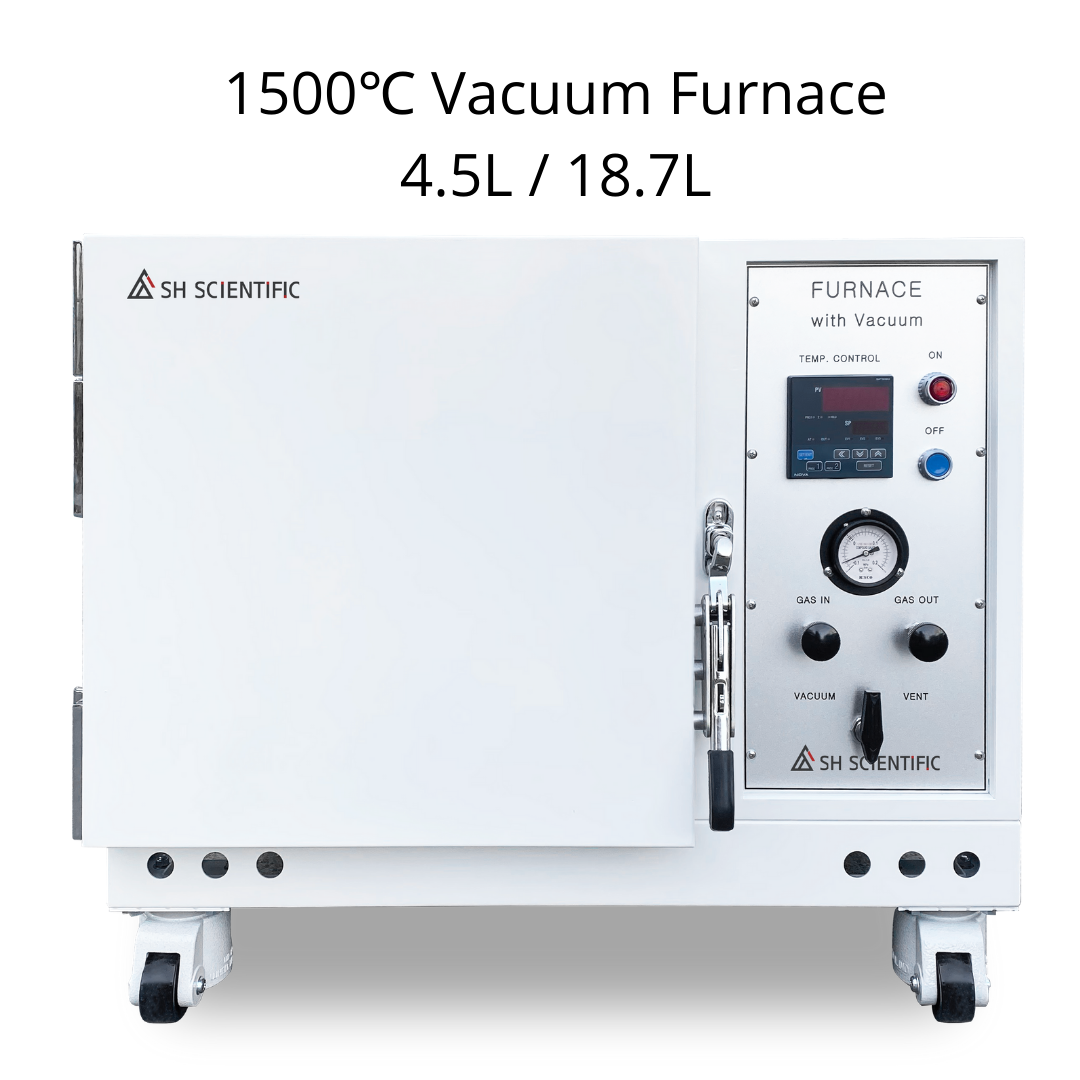

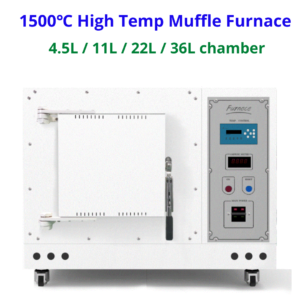

Specification

| Model | SH-FU-4.5MHV | SH-FU-18.7MHV |

| Max temperature | 1500℃ | 1500℃ |

| Continuous running temperature | 1350℃ | 1350℃ |

| Chamber volume | 4.5liters | 18.7liters |

| Controller | SP590 programmable controller | SP590 programmable controller |

| Heater | 3.3kW | 10.0kW |

| Sensor | R type | R type |

| Heating element | SIC | SIC |

| Insulation | Ceramic board & wool (ceramic fiber) | Ceramic board & wool (ceramic fiber) |

| Chamber size | 150x200x150mm | 250x300x250mm |

| External size | 630x590x830mm | 730x690x930mm |

| Option | Digital vacuum meter Mass flow controller Back pressure regulator |

Digital vacuum meter Mass flow controller Back pressure regulator |

| Power supply | 220V, 50/60Hz, 1p, 15A | 220V, 50/60Hz, 3p, 15A |